A Cleaner, More Organized Workspace: Adopting the 5S Housekeeping System

Maintaining an orderly and efficient workspace can significantly enhance productivity and safety. The 5S Housekeeping System, originating from Japan, offers a structured approach to achieving this goal. It consists of five phases: Sort, Set in Order, Shine, Standardize, and Sustain.

Sort (Seiri)

Creating an efficient and productive workspace begins with the principle of Sort (Seiri). This step involves identifying and removing unnecessary items from the work area, ensuring that only essential tools and materials are kept. By doing so, employees can focus better and work more efficiently. The first step in Sort (Seiri) is to evaluate all items in the workspace. This includes tools, documents, and equipment. Consequently, items that are not used regularly or do not contribute to the workflow should be removed or relocated.

Once unnecessary items are removed, the next step is to organize the remaining essential tools and materials. This can be done by categorizing items based on their usage frequency and ensuring they are easily accessible. This systematic approach ensures that the workspace remains clutter-free and optimized for productivity.

Set in Order (Seiton)

Organizing your workspace can significantly enhance productivity and efficiency. The principle of Set in Order (Seiton) focuses on arranging tools, materials, and equipment in a manner that promotes easy access and a streamlined workflow. To achieve this, begin by identifying the essential items needed for daily tasks. It is important to remove unnecessary clutter to create a more focused environment.

A place for everything, and everything in its place. - Benjamin Franklin

After identifying the essentials, assign specific locations for each item. Using labels, color-coding, or shadow boards can ensure that everything has a designated spot, making it easier to find and return items. This step is crucial in maintaining order.

Furthermore, optimize the layout by arranging items based on their frequency of use. For example, place frequently used tools within arm's reach, while storing less frequently used items in more distant locations. This thoughtful arrangement helps create an efficient and productive workspace, ultimately supporting a seamless and organized workflow.

Shine (Seiso)

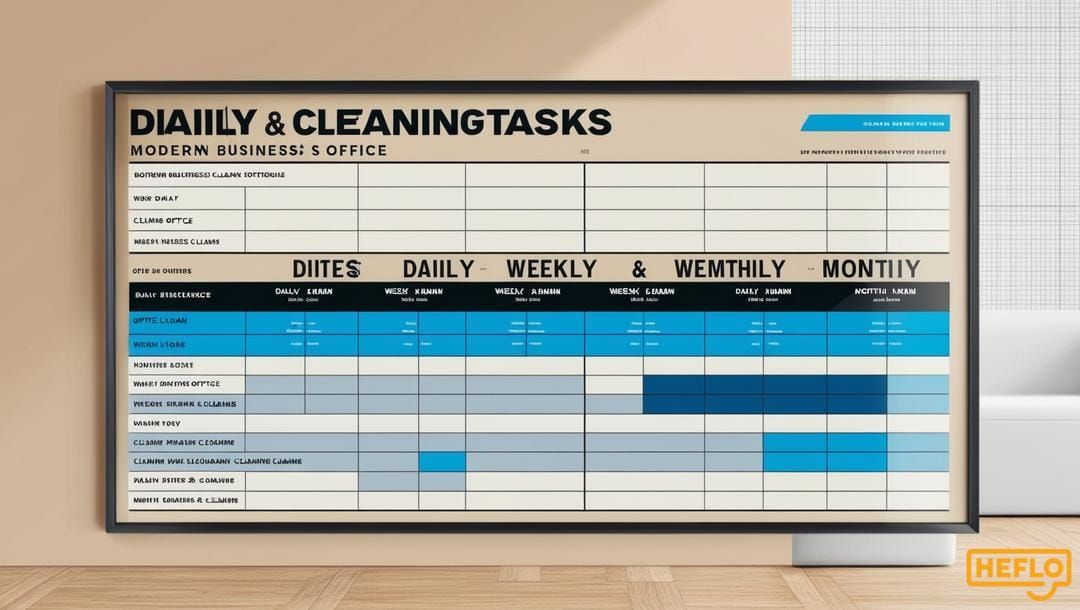

Maintaining a clean and organized workspace is essential for productivity and efficiency. The 5S Housekeeping System, particularly the 'Shine' or 'Seiso' phase, emphasizes the importance of cleanliness in the workplace. Shine (Seiso) involves thoroughly cleaning the workspace to ensure that all tools, equipment, and surfaces are free from dirt and debris. Not only does this step improve the appearance of the workspace, but it also helps in identifying potential issues such as leaks, wear, and damage.

To implement Shine effectively, it is crucial to establish a regular cleaning schedule and assign specific tasks to team members. Additionally, using checklists can ensure that all areas are covered, and maintaining a log can help track cleaning activities. This systematic approach to cleanliness promotes a healthier and more efficient work environment, ultimately supporting ongoing productivity and organizational efficiency.

For businesses looking to document and automate their cleaning processes, consider using HEFLO, a cloud-based business process management system. Learn more about HEFLO.

Standardize (Seiketsu)

Creating a consistent and uniform approach to maintaining cleanliness and organization is essential for any workspace. This is where the concept of Standardize (Seiketsu) comes into play. By establishing clear standards and procedures, everyone knows exactly what is expected, ensuring that the workspace remains orderly and efficient. To implement Standardize (Seiketsu), start by documenting the best practices for each task. This includes cleaning routines, storage methods, and equipment maintenance. It is important to make these procedures easily accessible to all employees, perhaps through visual aids or digital platforms.

Furthermore, utilize visual management tools such as labels, color-coding, and signage to reinforce standards. These visual cues help employees quickly identify where items belong and what steps to follow, thereby reducing confusion and errors. To ensure ongoing compliance with the established standards, conduct regular audits. These audits can be scheduled periodically and should involve checking that all procedures are being followed correctly. By integrating these steps, a workspace can maintain a high level of organization and efficiency, ultimately supporting a more productive work environment.

Sustain (Shitsuke)

Maintaining a clean and organized workspace requires consistent effort and discipline. The principle of Sustain (Shitsuke) emphasizes the importance of ingraining these practices into daily routines to ensure long-term success. To sustain a well-organized environment, it is essential to develop habits that reinforce the other 5S principles. Regular training sessions and reminders can help employees internalize these practices, making them second nature.

We are what we repeatedly do. Excellence, then, is not an act, but a habit. - Aristotle

In addition to embedding these habits, conducting periodic audits ensures that standards are being maintained. These audits can identify areas for improvement and reinforce the importance of adherence to established protocols. By combining regular training with audits, a workspace can continuously uphold high standards of cleanliness and organization, ultimately supporting ongoing productivity and efficiency.

Benefits of 5S Implementation

Implementing the 5S system can lead to numerous advantages for any workspace. This methodology, originating from Japan, focuses on five key principles: Sort, Set in Order, Shine, Standardize, and Sustain. By adhering to these principles, organizations can experience significant improvements in efficiency and productivity.

Enhanced Productivity

One of the primary benefits of 5S implementation is the boost in productivity. By organizing tools and materials systematically, employees spend less time searching for items, allowing them to focus more on their tasks.

Improved Safety

A well-organized workspace reduces the risk of accidents. Clear labeling and designated storage areas ensure that hazardous materials are handled properly, creating a safer environment for everyone.

Cost Reduction

By eliminating unnecessary items and optimizing the use of available resources, companies can significantly reduce waste and associated costs. This lean approach helps in better inventory management and minimizes overproduction.

Quality Control

Standardizing processes and maintaining cleanliness can lead to higher quality outputs. Consistent practices ensure that products meet quality standards, reducing defects and rework.

Challenges and Solutions in 5S Adoption

Implementing the 5S system can be a transformative process for any organization, but it often comes with its own set of challenges. Understanding these obstacles and finding effective solutions is key to a successful adoption.

The greatest obstacle to discovery is not ignorance - it is the illusion of knowledge. - Daniel J. Boorstin

Resistance to Change

One of the most common challenges is resistance from employees who are accustomed to existing workflows. To overcome this, it's essential to involve staff in the planning stages and provide comprehensive training.

Discover effective strategies for overcoming resistance to change by watching our insightful video—don't miss it!

Maintaining Consistency

Consistency in applying the 5S principles can be difficult to maintain over time. Regular audits and continuous improvement meetings can help ensure that standards are upheld.

Resource Allocation

Allocating sufficient resources, both in terms of time and budget, is another hurdle. Prioritizing 5S activities and integrating them into daily routines can make this more manageable.

Conclusion and Future Steps

As we reflect on the journey towards a more efficient and orderly environment, it's essential to consider the next steps to maintain and enhance these improvements. Continuous commitment and strategic planning are key to sustaining the benefits achieved. To begin with, regular audits and feedback loops can help identify areas for further enhancement. Encouraging team members to participate actively in suggesting improvements and reporting issues ensures that everyone is invested in the process.

Additionally, ongoing training sessions ensure that everyone remains aligned with the principles and practices. This not only reinforces the system but also empowers employees to take ownership of their workspace. Alongside training, integrating artificial intelligence can streamline processes such as inventory management and predictive maintenance. AI can provide data-driven insights, helping to optimize workflows and reduce waste.

Finally, establish clear, achievable goals for the future. These goals should be specific, measurable, and time-bound to ensure continuous progress and motivation among the team. By implementing these interconnected strategies, the organization can maintain and enhance the improvements achieved, fostering a culture of continuous improvement and efficiency.